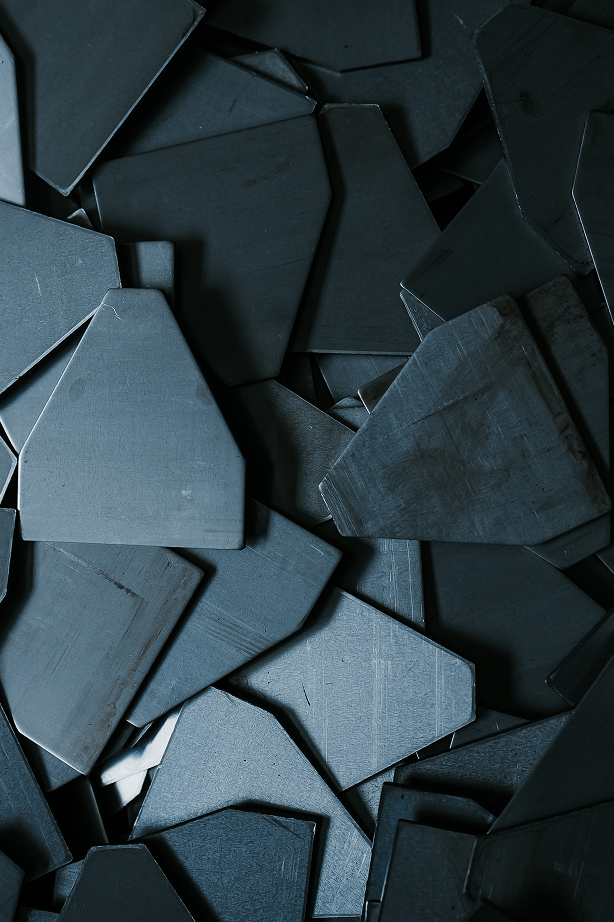

We work with machine manufacturers who expect reliability, repeatability, and full compliance with OEM specifications. Therefore, every detail is designed and manufactured with extreme operating conditions in mind – both in terms of

materials and processes.

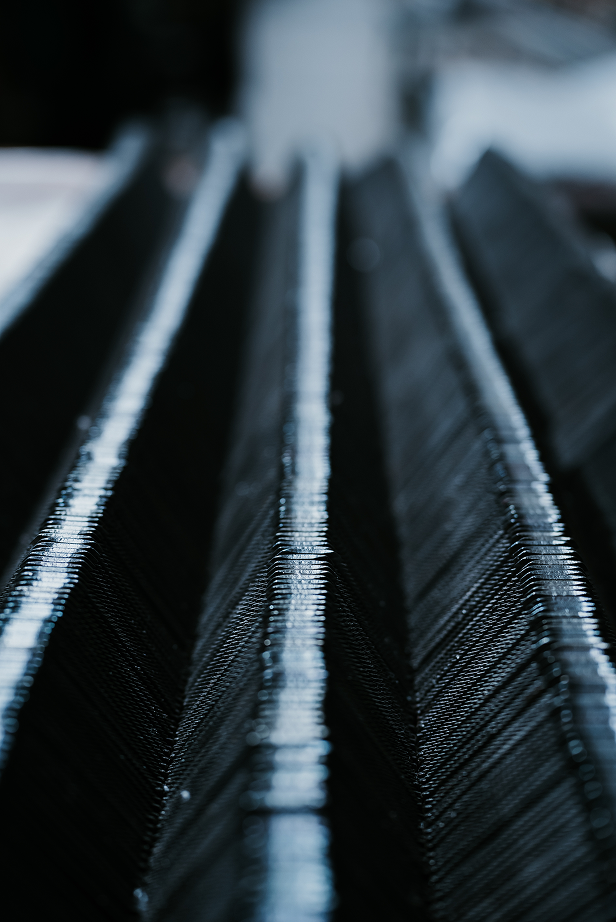

We use boron and chrome-vanadium steels, ensuring high resistance to abrasion and cracking.

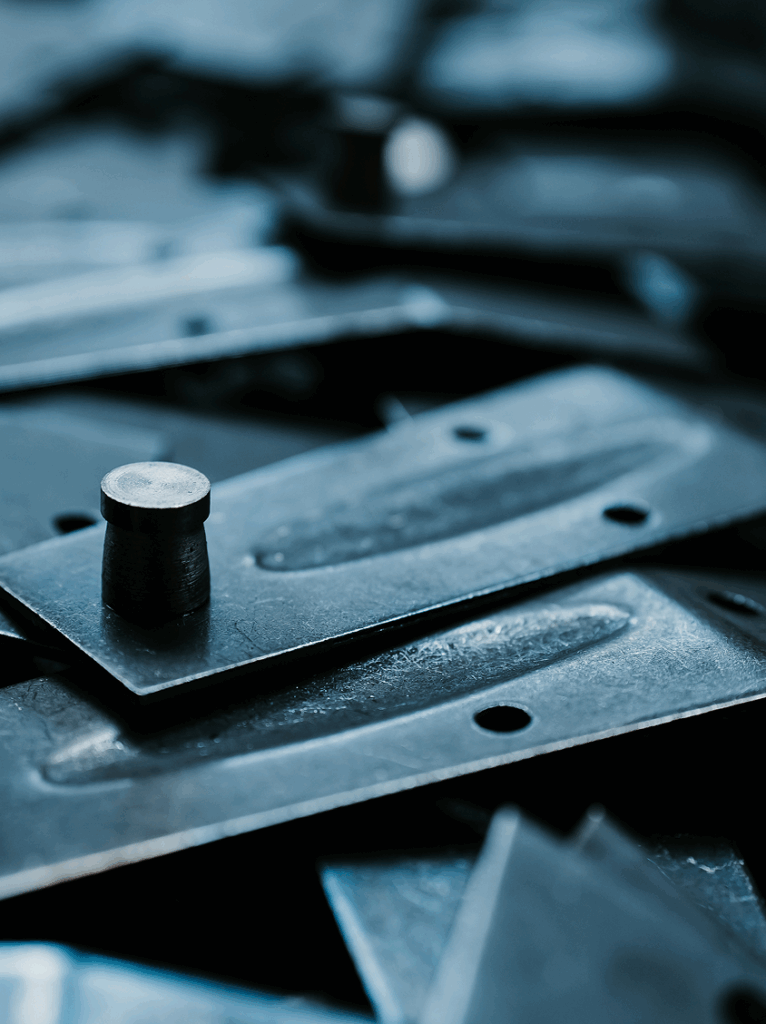

We produce either through-hardened or induction zone- hardened details, depending on the design intent – to achieve optimal hardness and flexibility.

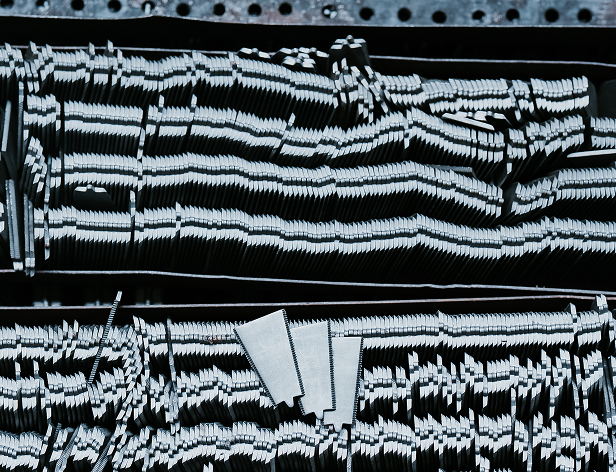

Precision laser cutting ensures consistent shape, while tungsten carbide (WC) coatings increase the durability of cutting edges even in the most demanding conditions.

We are ready to cooperate – from prototype to serial production.

Contact

tel. (+48) 48 375 51 63

OFFICE: gerpol@gerpol.agro.pl

SALES: sales@gerpol.agro.pl

PRODUCTION: produkcja@gerpol.agro.pl

MARKETING: marketing@gerpol.agro.pl

© 2025 GERPOL. All Rights Reserved.